Senzor digital ORP WHORP-768 | Monitorizare a potențialului redox de calitate industrială

Măsurare ORP de precizie concepută pentru medii dificile, senzor ORP MODBUS RTU pentru tratarea apelor uzate și multe altele

Folosind principiul ecuației Nernst, senzorul digital ORP WHORP-768 oferă o monitorizare fiabilă a potențialului de oxidare-reducere (ORP) în timp real.

Cu o precizie de măsurare de ±1 mV,

Clasificare de impermeabilitate IP68,

și integrare MODBUS RS485,

Acest senzor este conceput pentru aplicații solicitante în tratarea apelor uzate,

acvacultură, procesare chimică și monitorizare a mediului.

Caracteristici principale pentru fiabilitate industrială

- Gamă largă de măsurare

- Monitorizează ORP de la -1000 la 1000mV, ideal pentru urmărirea reacțiilor redox în diverse soluții.

- Măsoară temperatura de la 0 la 80 ℃ cu o precizie de ±5 ℃ pentru date complete despre mediu.

- Design robust și submersibil

- Clasificarea IP68/NEMA 6P permite imersia continuă (adâncime de 1 m) în medii corozive sau cu umiditate ridicată.

- Corpul din PP și cablul din PVC de 10 m rezistă coroziunii chimice și solicitărilor mecanice.

- Conectivitate Plug-and-Play

- Protocolul MODBUS RTU (RS485) permite integrarea perfectă cu PLC-uri, sisteme SCADA și platforme IoT.

- Compatibilitatea cu o gamă largă de tensiuni de 9–36 V CC reduce complexitatea instalării.

Specificații tehnice

| Parametru | Valoare |

| Raza de masurare | ORP: -1000–1000mV • Temperatură 0–80℃ |

| Precizie | ±1mV (ORP) • ±0,5℃ (Temperatură) |

| Alimentare electrică | 9–36 V CC |

| Protocol de ieșire | MODBUS RTU (RS485) |

| Material | Corp: PP • Cablu: PVC (10 m standard) |

| Dimensiuni | Φ30mm x 160mm |

| Greutate | 0,6 kg (cu cablu) |

| Clasificare impermeabilitate | IP68 |

| Presiune nominală | ≤0,6MPa (potrivit pentru instalații de conducte) |

| Temperatura de depozitare | 0–45℃ (mediu uscat) |

Aplicații

De încredere în industriile care necesită un control precis al potențialului redox:

Tratarea apelor uzateMonitorizarea eficienței dezinfecției (de exemplu, dozajul de clor) în stațiile de epurare.

În stațiile de epurare a apelor uzate, senzorul ORP WHORP – 768 MODBUS RTU joacă un rol crucial în monitorizarea eficienței dezinfecției. Acesta măsoară cu precizie nivelurile de ORP, permițând un control precis al dozajului de clor, esențial pentru menținerea standardelor de calitate a apei.

WHORP – 768, cu designul său submersibil IP68, este un instrument revoluționar pentru acvacultură. Rezistă la medii acvatice dure, permițând monitorizarea continuă și fiabilă a nivelurilor de ORP în acvariile de pești și creveți. Acest lucru ajută acvacultorii să optimizeze calitatea apei, reducând incidența bolilor cu până la 30%.

Prelucrare chimicăAsigurarea consecvenței reacțiilor în producția farmaceutică și alimentară.

O companie farmaceutică a implementat cu succes WHORP-768 în reactoarele sale. Prin controlul precis al potențialului redox cu acest senzor de monitorizare redox al reactorului farmaceutic, au obținut o reducere de 25% a defecțiunilor loturilor și un randament optimizat al API.

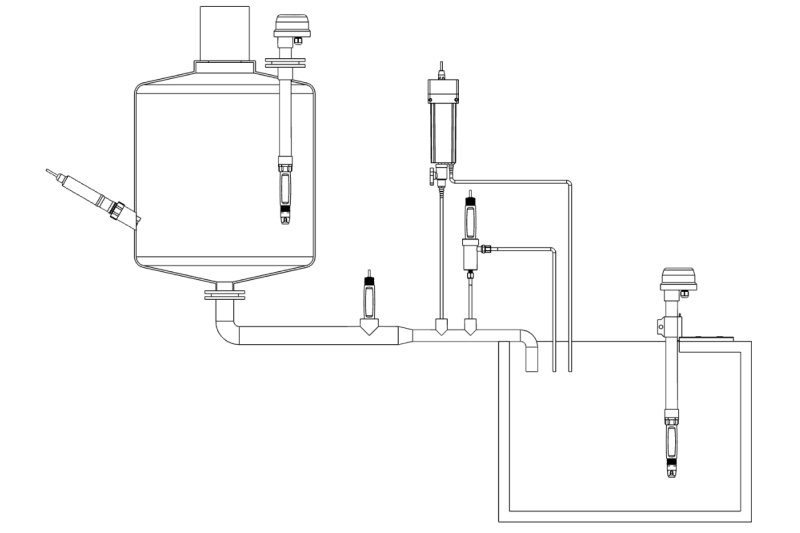

Ghid de instalare :Instalare fizică

Instalarea în reactoare, rezervoare de stocare, conducte sau sisteme de curgere – Asigurați imersia completă a electrodului

Notă: Înainte de utilizare, îndepărtați capacul protector acrilic deșurubându-l pentru a permite măsurarea.

Procedura de calibrare

- Pregătirea pre-calibrării:

- Curățați becul senzorului cu HCl 0,1N și clătiți cu apă deionizată.

- Se imersează într-o soluție standard de 235 mV (de exemplu, fericianură de potasiu) până când valorile se stabilizează.

- Calibrare MODBUS:

- Folosește codul funcției **06** în software-ul tău de monitorizare.

- Introduceți **Adresă: 5** și **Valoare: 2350** (235mV × 10 pentru precizie în milivolți).

- Confirmați „Răspuns OK” pentru a salva setările.

- Resetare din fabrică (dacă este necesar):

- IntrareAdresă: 200 şi Valoare: 1 prin MODBUS pentru a restaura parametrii impliciti.

Întreținere și îngrijire

- Curățenie de rutină

- Înmuiați becul de sticlă în HCl 0,1N timp de 10-15 minute pentru a îndepărta depunerile minerale.

- Ștergeți joncțiunea metalică cu o perie moale dacă este oxidată (evitați șmirghelul pe sticlă).

- Depozitare adecvată

- A se păstra într-o soluție de KCl 3,3M sau într-un capac protector umplut cu electrolit.

- Nu lăsați niciodată în lichide bogate în proteine (de exemplu, nămol de ape uzate).

- Verificări ale conexiunii

- Curățați blocurile terminale cu alcool izopropilic dacă sunt contaminate.

- Asigurați-vă că conexiunile cablurilor sunt uscate pentru a preveni scurtcircuitele.

- Semnale de înlocuire

- Înlocuiți dacă calibrarea eșuează după curățare sau dacă membrana de sticlă devine opacă.

De ce să alegeți seria CS2700?

- Precizie de vârf în industriePrecizie de ±1mV pentru controlul proceselor redox critice.

- Construcție durabilăClasificare IP68 și materiale rezistente la substanțe chimice pentru funcționare 24/7 în medii dure.

- Integrare ușoarăCompatibilitate MODBUS RS485 fără a fi necesare convertoare suplimentare.

- Întreținere redusă:Calibrați lunar (sau după cum este necesar) pentru a minimiza timpul de nefuncționare.

Solicitați o ofertă personalizată

→ Obțineți prețuri pentru WHORP-768 sau explorați ofertele noastre de pachete pentru sisteme complete de monitorizare.

Întrebări frecvente

Î: Cât de des ar trebui să calibrez senzorul ORP?

A:Calibrați la fiecare 2-4 săptămâni pentru uz industrial; verificări lunare sunt suficiente în medii stabile.

Î: Poate fi prelungit cablul senzorului peste 10 m?

R: Da, utilizați cablu RS485 ecranat până la 1000 m. Asigurați o împământare corespunzătoare pentru a menține integritatea semnalului.

Î: Ce ar trebui să fac dacă senzorul arată valori instabile?

R: Mai întâi, curățați becul cu HCl 0,1N și recalibrați. Dacă problemele persistă, restaurați setările din fabrică sau contactați asistența.

Î: Senzorul este compatibil cu acvacultura în apă sărată?

R: Da, designul cu grad de protecție IP68 și materialele rezistente la substanțe chimice îl fac potrivit pentru mediile marine.