Senzor digital de conductivitate WHEC-768 | Monitorizare industrială a calității apei

Măsurarea precisă a conductivității pentru sistemele industriale de apă

Proiectat pentru monitorizarea fiabilă a soluțiilor apoase,

Senzorul digital de conductivitate WHEC-768 oferă măsurători în timp real ale conductivității, TDS,

și temperatură. Cu o precizie de ±1%FS,

Grad de impermeabilitate IP68 și integrare MODBUS RS485,

Acest senzor este ideal pentru centrale electrice, procese chimice,

tratarea apei și aplicații industriale care necesită un control precis al calității apei.

Caracteristici principale

- Gamă largă de măsurare

- Conductivitate: 0–30.000µS/cm și 0–500.000µS/cm (capacitate de măsurare cu două intervale)

- Temperatură: 0–50℃ cu precizie de ±0,5℃ pentru date complete despre mediu

- Design submersibil robust

- Clasificarea IP68/NEMA 6P permite submersia continuă (adâncime de 1 m) în medii dure

- Corpul din PP și cablul din PVC de 10 m rezistă coroziunii chimice și solicitărilor mecanice

- Conectivitate inteligentă

- Protocol MODBUS RTU (RS485) pentru integrare perfectă cu PLC-uri, SCADA și platforme IoT

- Compatibilitate cu o gamă largă de tensiuni de 9–36 V CC pentru instalare flexibilă

Specificații tehnice

| Parametru | Valoare |

| Raza de masurare | Conductivitate: 0–30.000 µS/cm • 0–500.000 µS/cm • Temperatură: 0–50 ℃ |

| Precizie | ±1%FS (conductivitate) • ±0,5℃ (temperatură) |

| Alimentare electrică | 9–36 V CC |

| Protocol de ieșire | MODBUS RTU (RS485) |

| Material | Corp: PP • Cablu: PVC (10 m standard) |

| Dimensiuni | Φ30mm x 165mm |

| Greutate | 0,55 kg (cablu de 10 m inclus) |

| Clasificare impermeabilitate | IP68/NEMA 6P |

| Presiune nominală | ≤0,3MPa |

| Temperatura de depozitare | 0–45℃ (mediu uscat) |

| Calibrare | Calibrarea soluției standard în 2 puncte (de exemplu, 84µS/cm, 1413µS/cm) |

Aplicații

1. Desalinizarea marină

WHEC-768 joacă un rol esențial în instalațiile de desalinizare a apei de mare prin monitorizarea conductivității în sistemele de osmoză inversă (RO). Prin măsurarea conductivității apei de alimentare (de obicei 30.000–50.000µS/cm) și a conductivității permeatului (<100µS/cm), asigură o performanță optimă a membranei RO și o eficiență de respingere a sării. Designul său rezistent la substanțe chimice, cu grad de protecție IP68, rezistă la expunerea constantă la medii saline, reducând intervalele de întreținere cu 20%.

2. Fabricarea de electronice și semiconductori

În fabricarea semiconductorilor, apa ultrapură (UPW) cu conductivitate <0,1µS/cm este esențială pentru curățarea napolitanelor și fabricarea microcipurilor. WHEC-768 se integrează cu sistemele de electrodeionizare (EDI) pentru a monitoriza continuu procesele de schimb ionic, asigurând puritatea UPW și prevenind contaminanții care ar putea cauza defecte ale cipurilor. Compatibilitatea sa MODBUS RTU permite integrarea datelor în timp real cu sistemele de automatizare a fabricilor.

3. Sisteme de apă spitalicești

WHCOND-768 monitorizează sistemele de apă ale spitalelor în timp real, detectând modificările conductivității pentru a asigura calitatea apei și a preveni riscurile de contaminare.

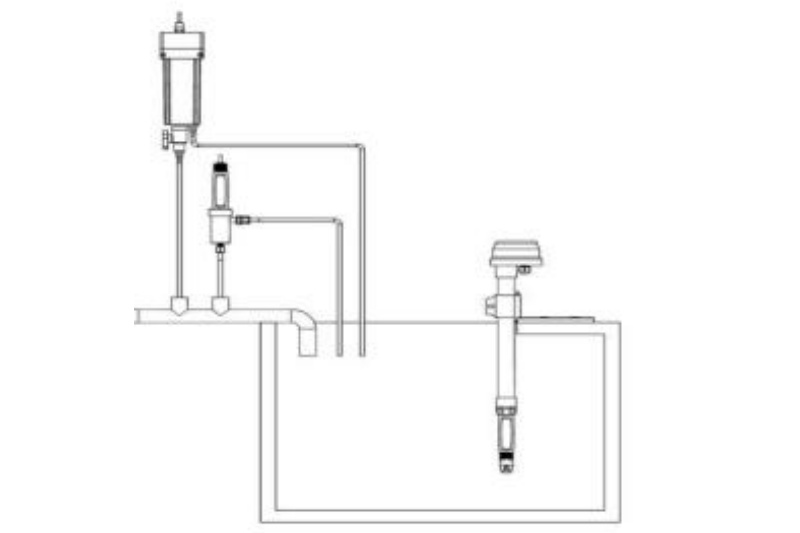

Ghid de instalare:

Cerințe de montare:

- Instalați vertical la o distanță de cel puțin 5 cm de fundul rezervorului/vasului pentru a evita interferența cu sedimentele.

- Utilizați o linie de bypass pentru sistemele cu debit mare pentru a asigura un debit stabil (250–500 mL/min)

- Managementul cablurilorSeparați cablurile RS485 de liniile de alimentare; extindeți până la 1000 m cu cablu ecranat

Procedura de calibrare:Calibrare la fața locului

- Prepararea soluțiilor standard:Utilizați fluide de calibrare de 84µS/cm (interval inferior) sau 1413µS/cm (interval superior)

- Pași de calibrare MODBUS:

- Scufundați senzorul în soluție până când citirile se stabilizează

- Folosiți codul funcției **06** pentru a introduce adresa **12** cu valoarea de calibrare (de exemplu, 1413 pentru 1413µS/cm)

- Confirmați „Răspuns OK” pentru a salva setările

- Calibrare în două puncte(pentru o precizie ridicată):

- Punctul 1: Adresa 24 pentru calibrare în interval inferior (de exemplu, 84µS/cm → intrarea 8)

- Al doilea punct: Adresa 25 pentru calibrare în interval înalt (de exemplu, 12,88 mS/cm → intrarea 1288)

Întreținere și îngrijire

- Curățenie de rutină:

- Spălați cu detergent cald 50% și o perie de nailon pentru a îndepărta depunerile organice

- Pentru depunerile persistente, înmuiați în soluție de 2% HCl (evitați electrozii de platină)

Îngrijirea electrodului de platină:

- Clătiți ușor cu apă deionizată; nu frecați niciodată cu perii

Depozitare:

- A se păstra într-un loc uscat sau în soluție de KCl 3,3M (pentru depozitare pe termen lung)

Verificări ale conexiunii:

- Asigurați-vă că terminalele sunt uscate; curățați cu alcool izopropilic dacă sunt contaminate

De ce să alegeți WHCOND-768?

- Versatilitate cu gamă dualăComutare între intervalele de conductivitate joasă/ridicată pentru diverse aplicații

- Durabilitate de calitate industrialăClasificare IP68 și materiale rezistente la substanțe chimice pentru funcționare 24/7

- Integrare Plug-and-PlayMODBUS RS485 pentru configurare rapidă cu sistemele de monitorizare existente

- Întreținere eficientă din punct de vedere al costurilorCalibrarea anuală și curățarea minimă reduc costurile operaționale

- Optimizați monitorizarea calității apei

→ Obțineți o soluție personalizată pentru nevoile dumneavoastră de monitorizare a conductivității – contactați echipa noastră astăzi!

- Întrebări frecvente

Î: Care este frecvența de calibrare recomandată?

A:Calibrați lunar pentru uz industrial; verificări trimestriale sunt suficiente în medii stabile.

Î: Poate senzorul să măsoare TDS?

R: Da, TDS poate fi derivat din citirile conductivității folosind un factor de conversie (configurabil prin MODBUS).

Î: Senzorul este compatibil cu apa cu salinitate ridicată?

R: Da, intervalul 0–500.000 µS/cm este compatibil cu soluții cu conductivitate ridicată, cum ar fi apa de mare și saramura.

Î: Cum se depanează citirile instabile?

A: Curățați electrozii cu detergent, recalibrați și verificați dacă există interferențe cu cablurile sau împământare necorespunzătoare.