WHEC-768 Digitális Vezetőképesség-érzékelő | Ipari Vízminőség-monitorozás

Precíziós vezetőképesség-mérés ipari vízrendszerekhez

Vizes oldatok megbízható monitorozására tervezve,

A WHEC-768 digitális vezetőképesség-érzékelő valós idejű méréseket biztosít a vezetőképességről, a TDS-ről,

és hőmérséklet. ±1%FS pontossággal,

IP68 vízállósági besorolás és MODBUS RS485 integráció,

Ez az érzékelő ideális erőművekhez, vegyipari feldolgozáshoz,

vízkezelés és ipari alkalmazások, amelyek precíz vízminőség-ellenőrzést igényelnek.

Alapvető jellemzők

- Széles mérési tartomány

- Vezetőképesség: 0–30 000 µS/cm és 0–500 000 µS/cm (kettős méréshatár tartomány)

- Hőmérséklet: 0–50 ℃, ±0,5 ℃ pontossággal az átfogó környezeti adatokhoz

- Robusztus merülő kialakítás

- Az IP68/NEMA 6P besorolás folyamatos merítést tesz lehetővé (1 m mélységig) zord környezetben

- A PP test és a 10 m-es PVC kábel ellenáll a kémiai korróziónak és a mechanikai igénybevételnek

- Intelligens csatlakozás

- MODBUS RTU (RS485) protokoll a PLC-kkel, SCADA-val és IoT platformokkal való zökkenőmentes integrációhoz

- 9–36 VDC széles feszültségkompatibilitás a rugalmas telepítés érdekében

Műszaki adatok

| Paraméter | Érték |

| Mérési tartomány | Vezetőképesség: 0–30 000 µS/cm • 0–500 000 µS/cm • Hőmérséklet: 0–50 ℃ |

| Pontosság | ±1%FS (vezetőképesség) • ±0,5 ℃ (hőmérséklet) |

| Tápegység | 9–36 V egyenfeszültség |

| Kimeneti protokoll | MODBUS RTU (RS485) |

| Anyag | Test: PP • Kábel: PVC (10 m standard) |

| Méretek | Φ30mm x 165mm |

| Súly | 0,55 kg (10 m-es kábellel) |

| Vízálló minősítés | IP68/NEMA 6P |

| Nyomásbesorolás | ≤0,3 MPa |

| Tárolási hőmérséklet | 0–45 ℃ (száraz környezet) |

| Kalibráció | 2 pontos standard oldat kalibráció (pl. 84µS/cm, 1413µS/cm) |

Alkalmazások

1. Tengeri sótalanítás

A WHEC-768 kritikus szerepet játszik a tengervíz sótalanító üzemekben a fordított ozmózis (RO) rendszerek vezetőképességének monitorozásával. A tápvíz vezetőképességének (jellemzően 30 000–50 000 µS/cm) és a permeátum vezetőképességének (<100 µS/cm) mérésével biztosítja az RO membrán optimális teljesítményét és a sóeltávolítási hatékonyságot. IP68-as besorolású, vegyszerálló kialakítása ellenáll a sós környezetnek való állandó kitettségnek, így 20%-vel csökkenti a karbantartási intervallumokat.

2. Elektronikai és félvezető gyártás

A félvezetőgyártásban a <0,1µS/cm vezetőképességű ultratiszta víz (UPW) elengedhetetlen a waferek tisztításához és a mikrochipek gyártásához. A WHEC-768 integrálható az elektródionizációs (EDI) rendszerekkel az ioncsere-folyamatok folyamatos monitorozása érdekében, biztosítva az UPW tisztaságát és megakadályozva a chiphibakat okozó szennyeződéseket. MODBUS RTU kompatibilitása lehetővé teszi a valós idejű adatintegrációt a gyári automatizálási rendszerekkel.

3. Kórházi vízrendszerek

A WHCOND-768 valós időben figyeli a kórházi vízrendszereket, érzékeli a vezetőképesség változásait a vízminőség biztosítása és a szennyeződés kockázatának megelőzése érdekében.

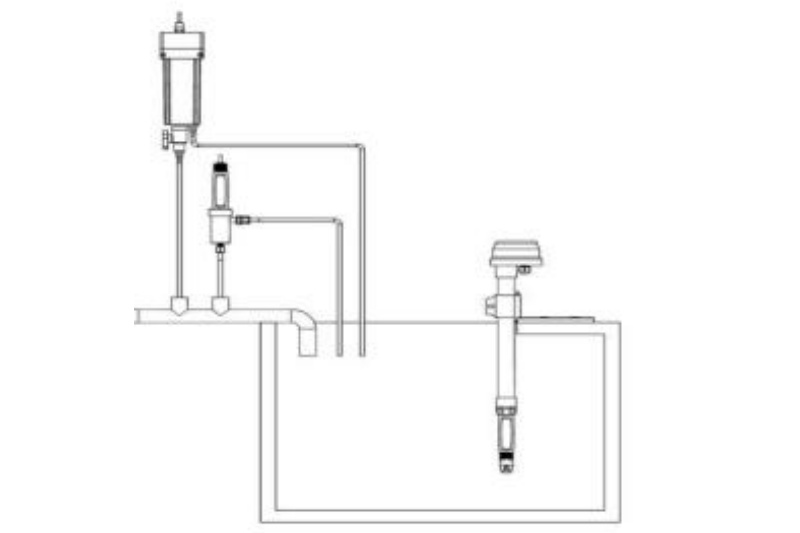

Telepítési útmutató:

Szerelési követelmények:

- Függőlegesen telepítse, legalább 5 cm távolságot tartva a tartály/tál aljától, hogy elkerülje az üledék zavarását

- Nagy áramlási sebességű rendszereknél használjon megkerülő csövet a stabil áramlási sebesség (250–500 ml/perc) biztosítása érdekében.

- KábelrendezésVálassza le az RS485 kábeleket a tápvezetékekről; árnyékolt kábellel akár 1000 m-ig is meghosszabbítható

Kalibrációs eljárás:Helyszíni kalibrálás

- Standard oldatok elkészítéseHasználjon 84µS/cm (alacsony tartomány) vagy 1413µS/cm (magas tartomány) kalibrációs folyadékot

- MODBUS kalibrálási lépések:

- Merítse az érzékelőt az oldatba, amíg a mérési eredmények stabilizálódnak

- Használja a **06** funkciókódot a **12** cím kalibrációs értékének megadásához (pl. 1413 1413µS/cm esetén)

- A beállítások mentéséhez erősítse meg a „Válasz OK” lehetőséget

- Kétpontos kalibráció(a nagy pontosság érdekében):

- 1. pont: 24-es cím az alacsony tartományú kalibráláshoz (pl. 84µS/cm → 8-as bemenet)

- 2. pont: 25-ös cím nagy tartományú kalibráláshoz (pl. 12,88 mS/cm → 1288-as bemenet)

Karbantartás és gondozás

- Rendszeres tisztítás:

- Mossa le 50% meleg mosószerrel és nejlonkefével a szerves lerakódások eltávolításához

- Makacs vízkő esetén áztassa 2% HCl oldatba (kerülje a platina elektródákat)

Platina elektróda ápolása:

- Óvatosan öblítse le desztillált vízzel; soha ne súrolja kefével

Tárolás:

- Száraz helyen tárolandó, vagy 3,3 M KCl oldatban tárolandó (hosszú távú tárolás esetén)

Kapcsolat-ellenőrzések:

- Győződjön meg róla, hogy a csatlakozók szárazak; ha szennyezettek, tisztítsa meg izopropil-alkohollal

Miért válassza a WHCOND-768-at?

- Kettős tartományú sokoldalúságVáltson alacsony/magas vezetőképességi tartományok között a különféle alkalmazásokhoz

- Ipari minőségű tartósságIP68 besorolás és vegyszerálló anyagok a 24/7-es működéshez

- Plug-and-Play integrációMODBUS RS485 a meglévő felügyeleti rendszerekkel való gyors beállításhoz

- Költséghatékony karbantartásAz éves kalibrálás és a minimális tisztítás csökkenti az üzemeltetési költségeket

- Optimalizálja vízminőség-ellenőrzését

→ Szerezzen személyre szabott megoldást vezetőképesség-monitorozási igényeire – vegye fel a kapcsolatot csapatunkkal még ma!

- GYIK

K: Mi az ajánlott kalibrálási gyakoriság?

A:Ipari használatra havonta kalibrálja; stabil környezetben a negyedéves ellenőrzés elegendő.

K: Tudja a szenzor mérni a TDS-t?

V: Igen, a TDS levezethető a vezetőképesség-mérésekből egy konverziós tényező segítségével (MODBUS-on keresztül konfigurálható).

K: Kompatibilis az érzékelő nagy sótartalmú vízzel?

V: Igen, a 0–500 000 µS/cm tartomány támogatja a nagy vezetőképességű megoldásokat, például a tengervizet és a sóoldatot.

K: Hogyan lehet elhárítani az instabil leolvasásokat?

A:Tisztítsa meg az elektródákat mosószerrel, kalibrálja újra, és ellenőrizze, hogy nincs-e kábelinterferencia vagy nem megfelelő földelés.